originally published September 24, 2012

In this four-part series of detailed questions about

Duradek Ultra Tiledek membranes

we first familiarized you with Tiledek, discussed the

alternative methods of waterproofing under exterior tile and why

Tiledek is the

stand-out option for doing it right the first time and guaranteeing that your deck waterproofing performs as intended.

In this fourth and final part of our

Tiledek series of articles we will discuss how to first prepare your deck surface to achieve waterproofing success.

How do you build a deck to make it is ready for tile?

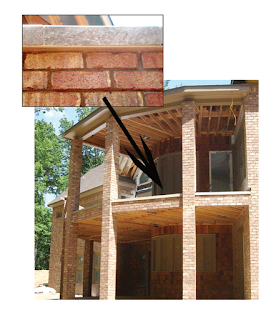

A major cause of failure of tile over decks and balconies is that the structure to which it is applied allows too much deflection. Tile has little tolerance for deflection. Cracking grout lines or tile is the result of deflection.

Deflection (the spring or give of the deck surface) is a product of the joist spacing and thickness of the flooring materials. The

Terrazzo, Tile and Marble Association of Canada (TTMAC) specification for flooring under tile or slate is as follows:

¾ inch plywood fastened with 2” #10 Exterior wood screws @6” oc @ perimeter and 8” oc @ joists covered with ½ inch cement board secured with thinset and fasteners. (The deck must have slope built in – suggested slope ¼” per foot)

The use of a cement board overlay is required/recommended by tile associations and manufacturers. Cement board, unlike plywood, is not affected by varying levels of moisture.

We strongly recommend that decks be built to this specification. For the money that is being invested in the whole system, it would seem unwise to scrimp on the subsurface. In case of a failure (cracking), the first thing anyone will look at (and blame it on) is whether the floor was strong enough and provided the necessary deflection resistance.

Concrete decks and balconies are suitable for tile application but still require proper waterproofing or roofing protection.

We recommend you follow the local best practice guidelines as laid out by the Tile Contractors Association of TTMAC or the building code. There may be regional differences in the suggested use of cement board or a second layer of plywood. As with all the details involved with a tile deck over a wood structure, you should follow the tile and thinset mortar manufacturer’s specifications.

Can tile be applied over an existing vinyl deck?

Most existing deck surfaces (PVC membrane or liquid applied finishes) are applied to 5/8 inch or ¾ inch plywood and therefore are not suitable for a tile overlay without some stiffening to reduce the deflection. The vinyl could be removed (possibly leaving the existing vinyl up the wall behind the siding and building paper), the floor stiffened with the appropriate thickness of cement board and the

Tiledek installed over top (special details will be published for this).

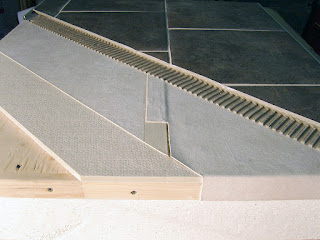

There is another system that can be used to stiffen the existing structure. Schluter’s ditra mat can be installed over top of

Tiledek (with thinset) and then the tile can be installed over top of Ditra. The Ditra mat stiffens the floor system to an appropriate level to provide for residential use of tile. We have tested this system with the Robinson Floor test and achieved a “residential” result.

Should you protect Tiledek until the tile is applied?

Like all products installed on a construction site,

Tiledek is susceptible to damage from other trades, scaffolding, paint, stucco, materials or tools being dropped from above or other abuse. Although

Tiledek is very tough (as we know from

Duradek) and can take a lot of abuse, it is always wise to protect it especially in heavy traffic areas or areas which are most likely to be damaged. Covering it with a protection board (plywood, recovery board etc) will save time and effort cleaning the

Tiledek to prepare it for accepting the tile overlay. A layer of polyethylene under the panels will protect the membrane from liquids (paints etc). Another method of protection would be to trowel apply directly to the

Tiledek a thin coating of the same thinset material that will be used to apply the tile or stone overlay.

How do you clean Tiledek if necessary?

If

Tiledek has been left exposed to traffic and construction debris and needs to be cleaned, it can be cleaned easily and effectively. Pressure washing with a light (1500 psi) spray with the nozzle no closer than 6 inches from the surface will work well. The surface can also be washed and lightly scrubbed with a bristle broom and hosed off.

Does the surface need to be sloped?

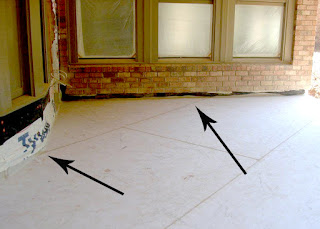

Yes! Sound roofing/waterproofing practice needs to be employed even when tile is applied over top. We operate on the expectation of water getting through the tile installation. Our membrane will be applied to a surface sloped towards drains, scuppers or an outside edge which allows the water to escape.

Moisture will still run downhill, even under tile applications. This can happen without negatively affecting the bond of the thinset mortar to the tile or the membrane.

We recommend the seams of the

Tiledek run parallel to the slope to avoid any water puddling up behind the bump.

Can a flat waterproof surface be re-sloped with a thickset application technique?

While it is possible to provide a slope with the thickset mortar, there are other problems to consider. If the waterproof membrane is flat or allows water to puddle on it, providing a sloped mortar bed will NOT remove all the water from the deck. Although most of the moisture will drain off the top surface, water WILL enter under the tile through cracks in the grout joints, cracks in the tile or on perimeters. The water that enters will follow the slope of the waterproofing membrane. If it puddles before the thickset mortar goes on, it will still puddle after the tile job is completed. The water will then just sit in a puddle and stagnate, potentially causing mould and an unpleasant odor to occur.

If you want to take a belly or depression out of the deck surface, it must be done prior to the Tiledek being installed. Since water will not penetrate

Tiledek, if the depression has been eliminated any water reaching it will be shed away.

Water testing before the Overlay is Applied

We recommend a water test be done after the

Tiledek is installed and prior to the overlay being applied.

Conclusion

If you have read all four parts of this series of articles on

Tiledek and waterproofing methods for exterior tile projects, you are well equipped to ask all of the right questions to all parties involved in the construction of a reliable and long-lasting outdoor tile deck.

At Duradek we believe that

your deck should be a source of pleasure, not stress, and we encourage all home owners and builders to ensure they do it right the first time….do it with

Duradek Ultra Tiledek.