Serving Greater Auckland, Northland and Waikato, Deck Masters New Zealand specializes in residential and commercial waterproofing and maintenance solutions for new and existing buildings. With an exceptional team of skilled professionals, Deck Masters NZ is led by Terry Hugill with a goal to surpass customer expectations with both project time and product performance.

|

| View deck with Duradek Supreme Chip Granite vinyl at Red Beach. |

It is Deck Master NZ’s dedication to using only the highest quality waterproofing products that led them to Duradek™ vinyl deck membranes which have been successfully used in North America for over 40 years. Originally conceived by two outdoor enthusiasts inspired by the marine vinyl in their fishing boat (read the Duradek Story for more details), Duradek is the original vinyl decking and essentially created a niche specialty trade.

Having pioneered the vinyl decking industry, Duradek president John Ogilvie was instrumental in establishing North American building codes for the use of Duradek as a roofing membrane, making Duradek the definitive authority on “walkable roofing membranes”. Duradek is also one of the only vinyl decking products that offers an appearance warranty in addition to guaranteeing waterproof performance.

|

| Deck with Duradek Supreme Chip Taupe vinyl in Chatswood. |

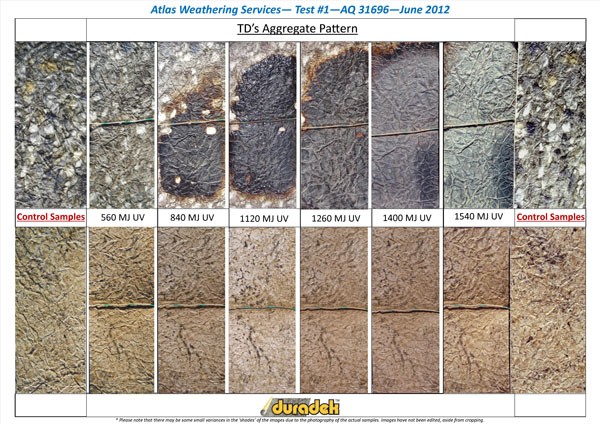

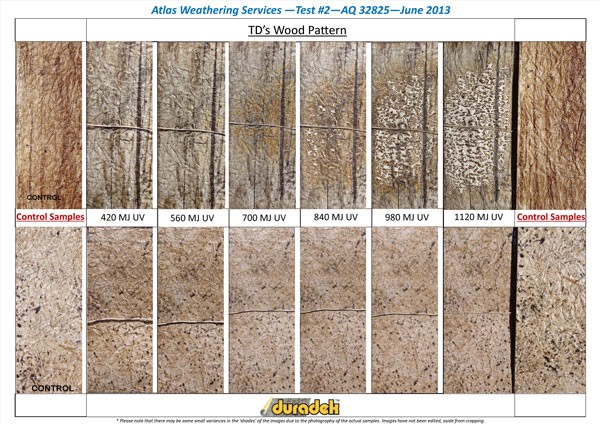

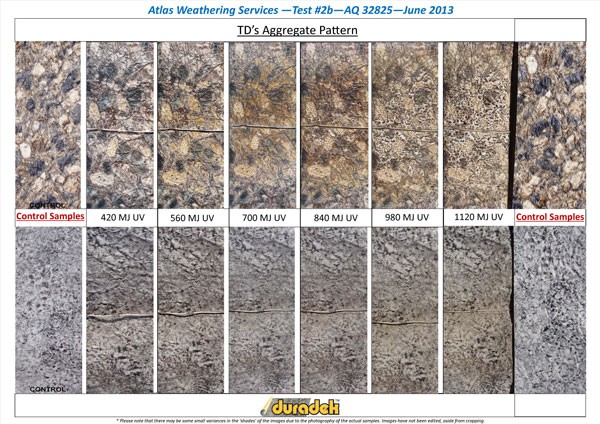

Duradek vinyl recently took the initiative in some extensive product testing above building code requirements and went head to head with competing vinyl brands in accelerated weather testing to clearly demonstrate that Duradek vinyl decking stands up to UV exposure better than any other deck vinyl.

An additional feature that makes Duradek vinyl a superior choice for a deck, balcony or roof deck waterproofing is the fact that Duradek is not available as a retail product for do-it-yourself projects. The team at Duradek knows that no matter how superior a waterproofing product is manufactured; it is the installation details and techniques that ensure the waterproofing performs as intended. This is what made Deck Masters NZ such a perfect fit to become New Zealand’s source for Duradek vinyl decking.

|

| Duradek training session with Miles from Deck Master New Zealand |

Deck Master NZ already had an existing team of professionals skilled in deck and roof waterproofing and they invested in sending their team representative, Miles Hugill, to Duradek’s headquarters. Located in Surrey, BC (part of the Greater Vancouver Regional District in western Canada), Duradek’s home base is one of the most beautiful, but rainiest climates in North America - a fitting place to perfect waterproofing details. While visiting Duradek headquarters, Miles was busy learning the specific techniques that Duradek has mastered to ensure reliable waterproof performance, which he took back to the team at Deck Master NZ.

The waterproofing specialists at Deck Masters NZ introduced Duradek at the Auckland Home Show in September and have been busy with installations in the Greater Auckland area throughout the summer.

|

| Deck Master NZ at the Auckland Home Show 2015. |

With shorelines and rolling countryside that is the envy of the whole world, New Zealanders already enjoy the best of outdoor living - and now they can bring that to their own homes. By offering Duradek vinyl membranes to New Zealanders, Deck Masters NZ is opening up opportunity for home owners to enjoy the most leisure time on the decks, balconies, patios and porches without the need for ongoing maintenance to ensure waterproof performance remains intact.

|

| Roof Deck in Orewa with Duradek Okanagan Flint vinyl. |

So, kick back with an L&P or favourite local brew and enjoy a life of leisure with a maintenance-free, waterproof deck from Deck Masters New Zealand!

Contact Deck Masters New Zealand, LLC for a no-obligation estimate on your decking project in Greater Auckland.

Call 09 281 5830 or inquire online.